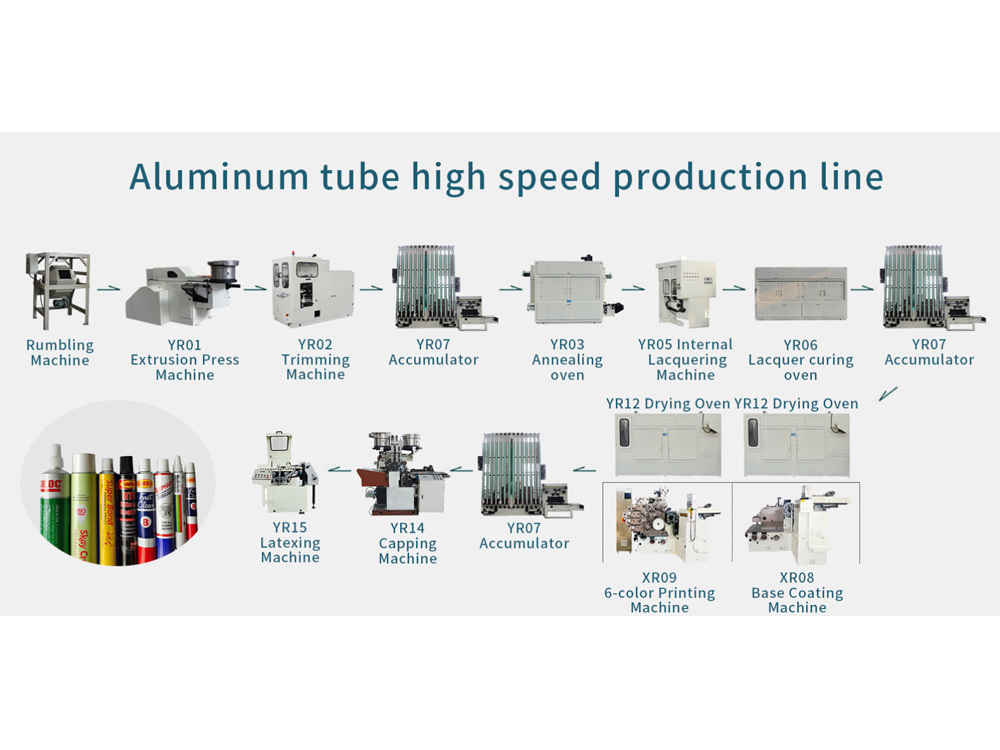

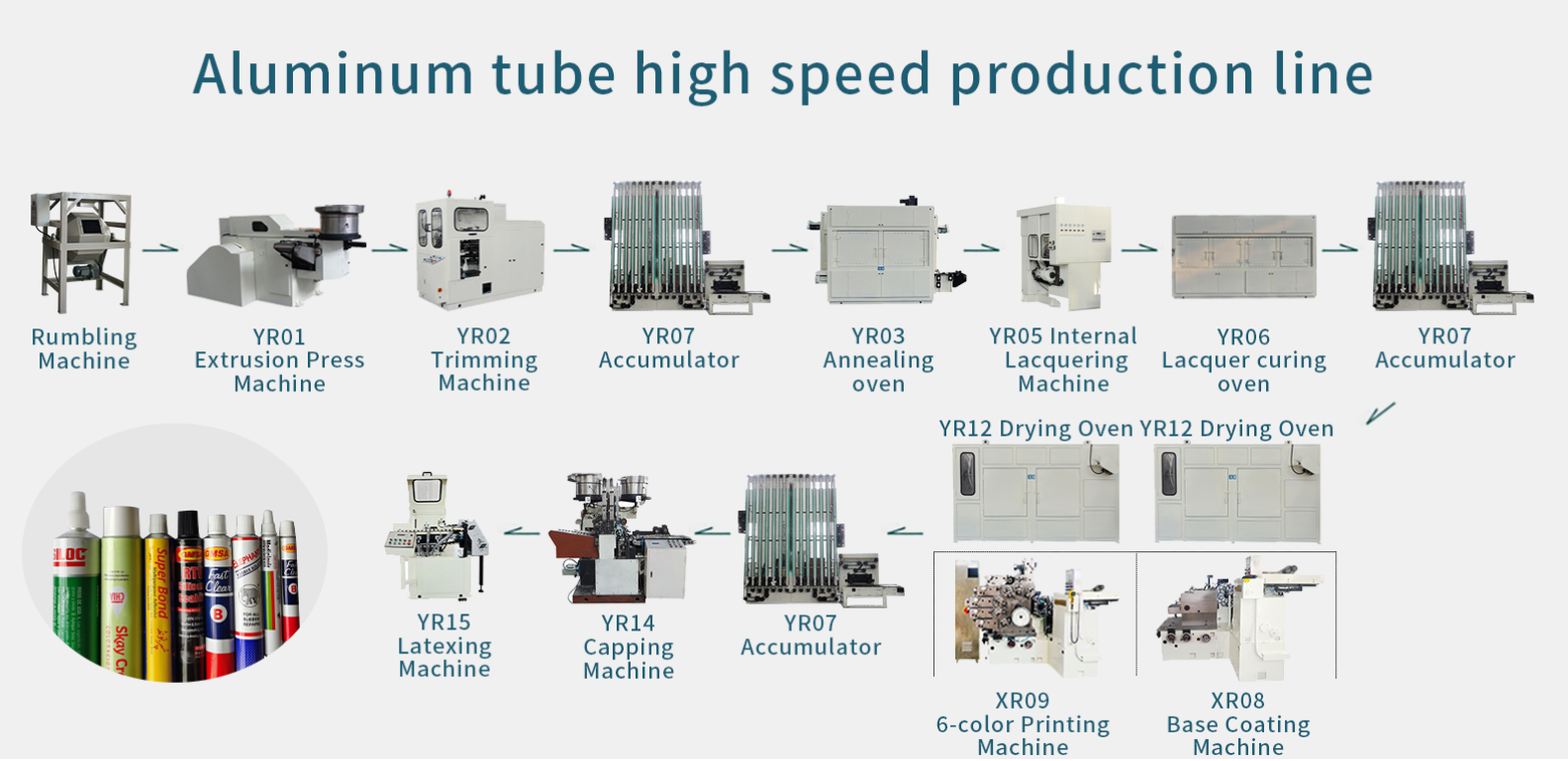

Aluminum tube high speed production line

- Product description

-

- Commodity name: Aluminum tube high speed production line

This production line is composed of Vibrating Screening Plate, Extrusion Press Machine,Trimming Machine,Accumulator,Annealing oven,Lacquer curing oven,Base Coating Machine,Printing Machine,Capping Machine,Latexing Machine. The production speed is 90-120 pieces/min.

This production line is composed of Vibrating Screening Plate, Extrusion Press Machine,Trimming Machine,Accumulator,Annealing oven,Lacquer curing oven,Base Coating Machine,Printing Machine,Capping Machine,Latexing Machine. The production speed is 90-120 pieces/min.

The vibrating screen disc screens the aluminum discs and enters The extrusion press machine to squeeze them into tubes, then The trimming machine cuts out the threads of the nozzle and polishes the tube body, and then enters The accumulator storage for storage during shutdown. During the production process, the storage is directly connected to The annealing oven, and the aluminum tube undergoes high-temperature softening treatment in The annealing oven, and then internal spraying (mainly used for anti-corrosion and hygiene and safety) through The internal lacquering machine, and then high-temperature internal drying through The lacquer curing oven. The dried tube passes through The accumulator to color the tube through background color, printing and other processes (six or eight color printing is possible). In the two processes of background color and printing, each process is required The drying oven is for drying operation, so a gantry platform is placed above the two machines, and The two drying ovens are placed on the platform, corresponding to The base coating printing machine and The printing machine. The colored aluminum tube is then led to the cap twisting process from the storage, the cap is screwed on the aluminum tube by The capping machine, and finally The latexing machine is evenly sprayed with glue on the inner wall of the aluminum tube tail and then packaged and sealed.

The main configuration of the production line:

Configuration Brand PLC SIEMENS Touch screen SIEMENS Inverter DANFOSS, YASKAWA

(for big tube 150T Extrusion Press Machine)Proximity switch TURCK Rotary encoder KOYO Pneumatic components FESTO Main bearing NSK/NTN Photoelectric switch BANNER Burner SICO

Inquiry

Attention: Please leave your email and our professionals will contact you as soon as possible!