Manufacturing process of aluminum aerosol cans equipment

In today's packaging industry, single-piece aluminum aerosol cans have become a popular packaging choice for many products due to their lightweight, durable, and recyclable nature.

Release time:

2025-05-26

Manufacturing process of aluminum aerosol cans

In today's packaging industry, single-piece aluminum aerosol cans have become a popular packaging choice for many products due to their lightweight, durable, and recyclable nature. So, why are aluminum aerosol cans so popular? In this article, we will delve into the manufacturing process of aluminum aerosol cans and the industry's technology to help you understand the secrets behind them.

Advantages of Aluminum Aerosol Cans

First, the advantages of single-piece aluminum aerosol cans are undeniable. The lightweight nature of aluminum significantly reduces transportation costs. Furthermore, aluminum aerosol cans have excellent corrosion resistance, effectively extending the shelf life of the products. This is like a set of high-quality protective gear that protects the "treasure" inside in harsh environments.

Moreover, aluminum is a renewable resource. Using aluminum aerosol cans is not only environmentally friendly but also attracts consumers who focus on sustainable consumption. The increasing environmental awareness has prompted more and more companies to choose aluminum aerosol cans as product packaging, perfectly combining functionality with environmental concepts.

Meticulous Manufacturing Process

So, how are aluminum aerosol cans manufactured? This process is actually quite complex, and every step from the selection of raw materials to the completion of the finished product cannot be careless.

First, high-quality aluminum alloy is selected as the main raw material. Then, through advanced stamping technology, the basic structure of the single-piece aluminum aerosol can is formed. This step is like a sculptor meticulously carving on marble; any small flaw may affect the final appearance and usability.

Precise Forming and Spraying Processes

After forming, the spraying process adds color and a protective layer to the aerosol can. This process not only enhances aesthetics but also improves the wear resistance of the aluminum aerosol can. Imagine it like painting a new car—it needs to be both beautiful and durable.

At the same time, strict quality checks are carried out during the manufacturing process. Each batch of production must undergo thorough testing to ensure the airtightness and safety of the product. This meticulous attitude is like a chef carefully tending to each dish in the kitchen, never allowing any mistakes.

Industry Technological Innovation

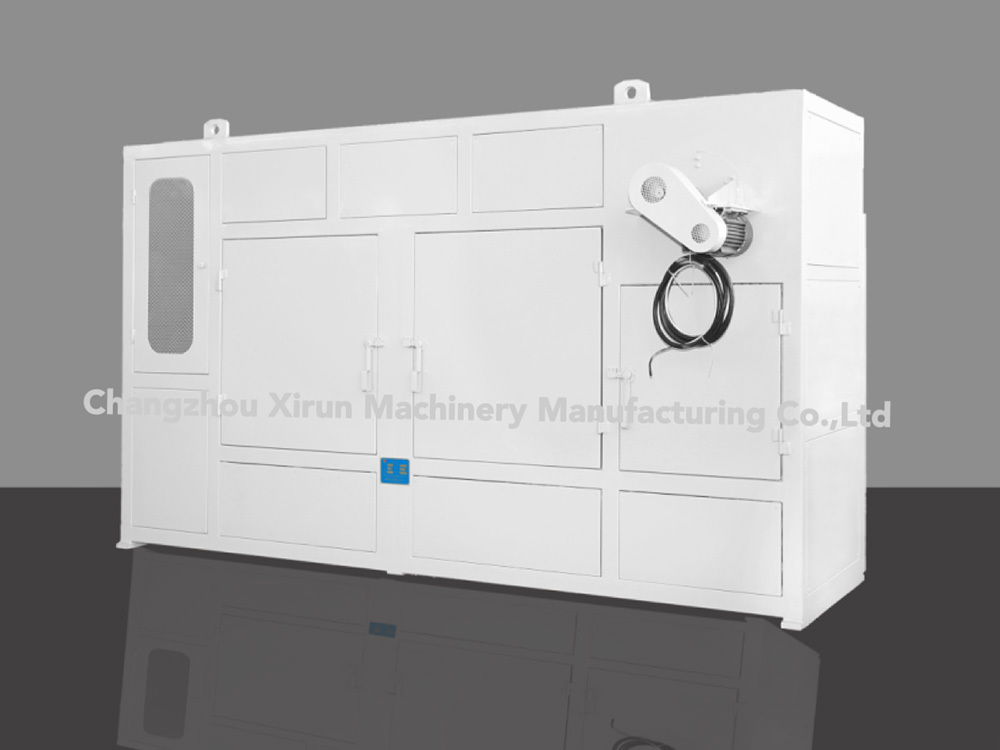

With continuous technological advancements, the manufacturing process of aluminum aerosol cans is constantly innovating. For example, some companies are now introducing automated production lines, significantly improving production efficiency. This is like switching from a traditional manual car to an automatic driving car—it saves time and effort and reduces human error.

In addition, intelligent equipment makes data monitoring during the production process more accurate, providing real-time feedback on the production status. The application of this technology not only improves production efficiency but also saves companies a lot of labor costs.

Market Demand and Future Development Trends

According to market research, the demand for single-piece aluminum aerosol cans continues to grow in multiple fields such as cosmetics and cleaning agents. Therefore, manufacturers of aluminum aerosol cans are also constantly exploring new application areas. In the future, we may see more aluminum aerosol cans in the food and pharmaceutical industries.

In summary, the advantages and manufacturing process of aluminum aerosol cans have made it an indispensable part of the industry. With continuous technological advancements, we have reason to believe that the future of aluminum aerosol cans will be even brighter.

Previous Page

Previous Page

Latest Blog