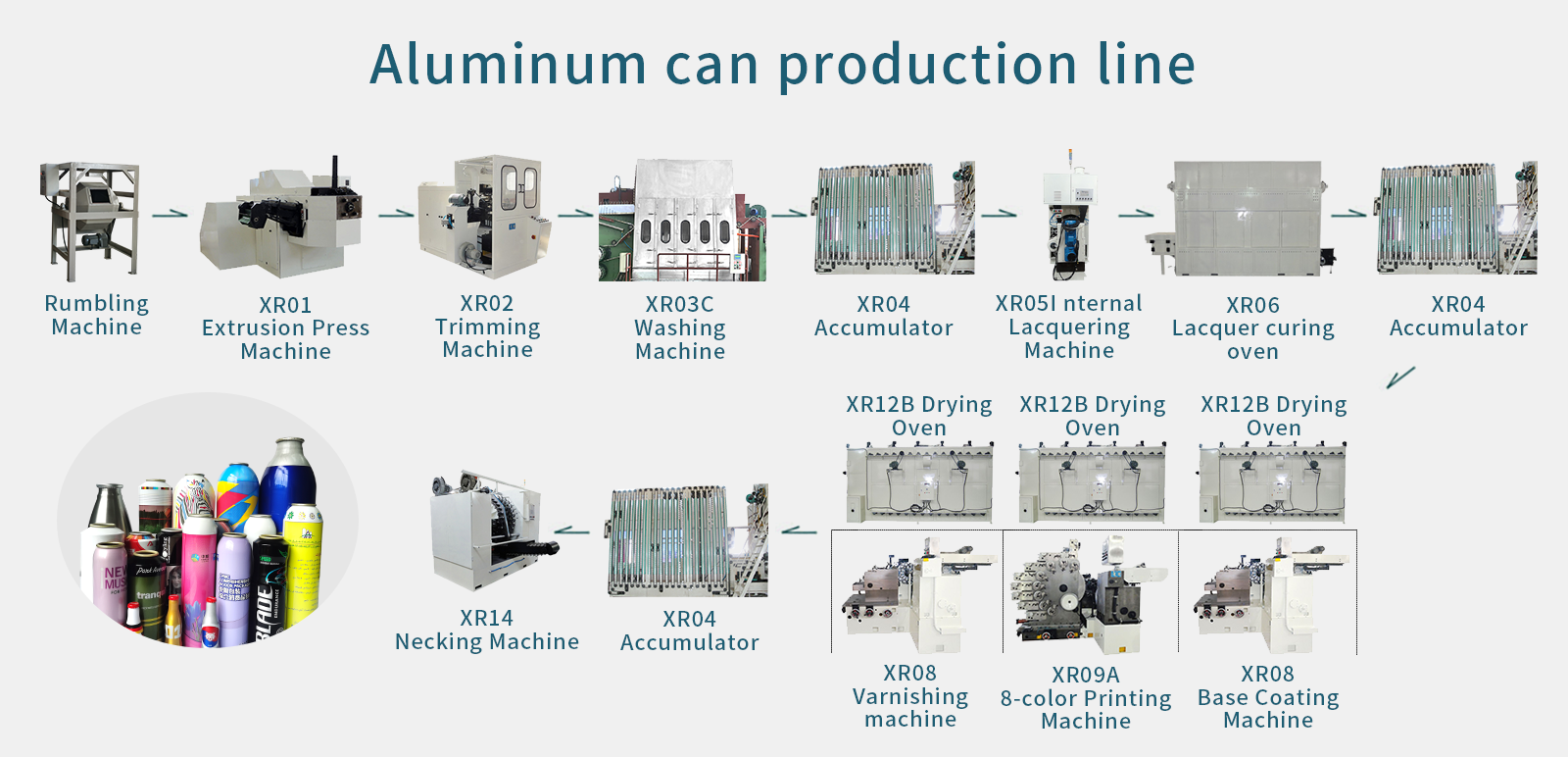

Aluminum can production line

This production line consists of Rumbling Machine,Hoist,Extrusion Press Machine,Trimming Machine,Washing Machine,Accumulator,Internal Lacquering Machine,Lacquer curing oven,Base Coating Machine,Printing Machine,Varnishing machine,Drying Oven and Necking Machine .The production speed is 90-120 cans/min.

After fully lubricating the aluminum wafers, the slicer enters The Extrusion Press Machine through the elevator and extrudes them into aluminum cans, and then trims the irregular mouth of the aluminum cans and polishes the can body by The Trimming Machine. Because aluminum cans will generate dust during the production process, in order to ensure that the subsequent processes can be better carried out, the aluminum cans need to be cleaned and dried in The Washing Machine with cleaning fluid, and then stored through The Accumulator when it is ready to stop. During the production process, the aluminum cans on the storage will be sent to The Internal Lacquering Machine for internal spraying (mainly used for anti-corrosion and hygiene and safety), and then passed through The Lacquer curing oven for high-temperature internal drying, and passed the background color and printing through The Accumulator,Varnish and other processes to color aluminum cans (six-color or eight-color printing can be performed). In the three processes of background color, printing, and varnish, each process requires a Drying Oven for drying operation, so in these three A gantry platform is placed above the machine, and three Drying Ovens are placed on the platform, corresponding to The Base Coating Machine, The Printing Machine and The Varnishing Machine. The colored aluminum cans then pass from The Accumulator to the last necking process, and finally The Necking Machine (30 stations or 36 stations) will shrink the can mouth into a finished product and then pack and seal the box together.

The main configuration of the production line:

| Configuration | Brand |

| PLC | SIEMENS |

| Touch screen | SIEMENS |

| Inverter | DANFOSS, YASKAWA (for Extrusion Press Machine) |

| Proximity switch | TURCK |

| Rotary encoder | KOYO |

| Pneumatic components | FESTO |

| Main bearing | NSK/NTN |

| Photoelectric switch | BANNER |

| Thermostat | FUJI |

| Burner | SICO |

Changzhou Xirun Machinery Manufacturing Co., Ltd

Changzhou Yunjie Machinery Manufacturing Co., Ltd

Wuxi Pengrun Machinery Manufacturing Co., Ltd

Tel:

E-mail:

Address:

锡润机械

Copyright: Changzhou Xirun Machinery Manufacturing Co., Ltd. 苏ICP备2021018246号-1

13861874189

13861874189

Message

Message