Enhancing Efficiency: The Role of Trimming Machines in Metal Packaging

In the packaging and printing industry, especially when dealing with metal packaging materials like aluminum and aluminum alloys, the importance of trimming machines cannot be overstated. These machines play a crucial role in ensuring that aluminum sheets and other metal products are processed to meet specific dimensions and quality standards. Trimming machines are designed to cut excess material

Release time:

2026-01-20

In the packaging and printing industry, especially when dealing with metal packaging materials like aluminum and aluminum alloys, the importance of trimming machines cannot be overstated. These machines play a crucial role in ensuring that aluminum sheets and other metal products are processed to meet specific dimensions and quality standards.

Trimming machines are designed to cut excess material from the edges of metal sheets, providing a clean and precise finish that is essential for various applications. In the context of aluminum packaging, which is often used for food and beverage containers, achieving the right dimensions is vital for maintaining product integrity, appearance, and consumer safety.

One of the primary advantages of using trimming machines is their ability to enhance production efficiency. By automating the trimming process, manufacturers can significantly reduce manual labor, minimizing human error and increasing output rates. This not only saves time but also allows for greater consistency in the dimensions of the final products. In an industry where precision is key, trimming machines ensure that every piece meets the required specifications.

Another important aspect of trimming machines is their adaptability. Many modern machines come equipped with advanced technology, allowing them to handle various thicknesses and types of aluminum materials. This flexibility means that manufacturers can cater to a diverse range of products without needing multiple machines for different tasks. Furthermore, the integration of digital controls and automated features enhances operational efficiency and reduces the likelihood of production delays.

Moreover, trimming machines contribute to waste reduction. By ensuring that cuts are made precisely, manufacturers can maximize the use of their raw materials, minimizing scrap and lowering overall production costs. This aligns with sustainability goals, as reducing waste in the production process is increasingly important in today’s environmentally conscious market.

In addition to efficiency and waste reduction, trimming machines also improve the overall quality of the finished products. A well-trimmed edge is not only visually appealing but also plays a critical role in the functionality of the packaging. For example, improper trimming can lead to sharp edges that pose hazards during handling or transportation. Trimming machines ensure that edges are smooth and safe, enhancing the user experience and minimizing risks.

In summary, trimming machines are an essential component in the metal packaging industry, particularly for aluminum and aluminum alloy materials. They enhance efficiency, reduce waste, and improve product quality, making them invaluable tools for manufacturers. As the demand for high-quality packaging continues to rise, the role of trimming machines will only become more significant, driving innovation and excellence in the sector. Understanding these machines and their benefits is crucial for businesses aiming to optimize their production processes and maintain a competitive edge in the market.

Trimming machines are designed to cut excess material from the edges of metal sheets, providing a clean and precise finish that is essential for various applications. In the context of aluminum packaging, which is often used for food and beverage containers, achieving the right dimensions is vital for maintaining product integrity, appearance, and consumer safety.

One of the primary advantages of using trimming machines is their ability to enhance production efficiency. By automating the trimming process, manufacturers can significantly reduce manual labor, minimizing human error and increasing output rates. This not only saves time but also allows for greater consistency in the dimensions of the final products. In an industry where precision is key, trimming machines ensure that every piece meets the required specifications.

Another important aspect of trimming machines is their adaptability. Many modern machines come equipped with advanced technology, allowing them to handle various thicknesses and types of aluminum materials. This flexibility means that manufacturers can cater to a diverse range of products without needing multiple machines for different tasks. Furthermore, the integration of digital controls and automated features enhances operational efficiency and reduces the likelihood of production delays.

Moreover, trimming machines contribute to waste reduction. By ensuring that cuts are made precisely, manufacturers can maximize the use of their raw materials, minimizing scrap and lowering overall production costs. This aligns with sustainability goals, as reducing waste in the production process is increasingly important in today’s environmentally conscious market.

In addition to efficiency and waste reduction, trimming machines also improve the overall quality of the finished products. A well-trimmed edge is not only visually appealing but also plays a critical role in the functionality of the packaging. For example, improper trimming can lead to sharp edges that pose hazards during handling or transportation. Trimming machines ensure that edges are smooth and safe, enhancing the user experience and minimizing risks.

In summary, trimming machines are an essential component in the metal packaging industry, particularly for aluminum and aluminum alloy materials. They enhance efficiency, reduce waste, and improve product quality, making them invaluable tools for manufacturers. As the demand for high-quality packaging continues to rise, the role of trimming machines will only become more significant, driving innovation and excellence in the sector. Understanding these machines and their benefits is crucial for businesses aiming to optimize their production processes and maintain a competitive edge in the market.

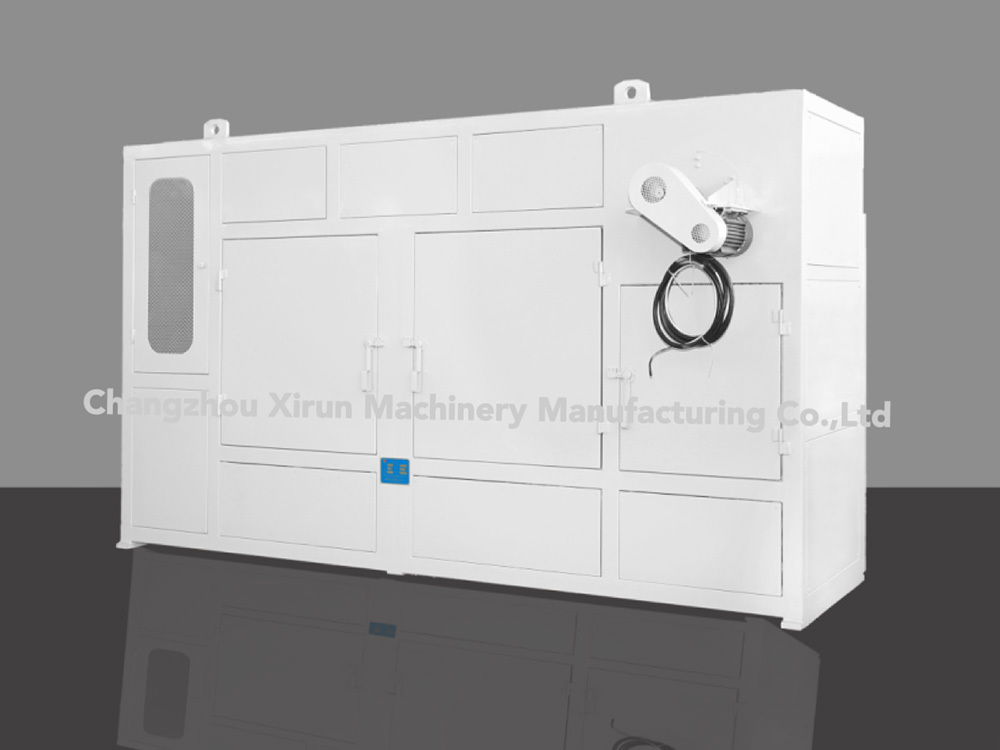

trimming machine

Latest Blog