The Essential Guide to Internal Lacquering Machines for Metal Packaging

Internal lacquering machines are crucial in the production of metal packaging, particularly for aluminum and aluminum alloy containers. These machines apply a protective lacquer coating to the interior surfaces of metal packages, which serves multiple functions, including enhancing product safety, ensuring the integrity of the packaging, and improving the overall aesthetic appeal of the product. O

Release time:

2026-01-24

Internal lacquering machines are crucial in the production of metal packaging, particularly for aluminum and aluminum alloy containers. These machines apply a protective lacquer coating to the interior surfaces of metal packages, which serves multiple functions, including enhancing product safety, ensuring the integrity of the packaging, and improving the overall aesthetic appeal of the product.

One of the primary functions of an internal lacquering machine is to prevent contamination. The lacquer coating acts as a barrier between the metal and the contents within, thereby preventing any reactions that could compromise the quality of the product. This is especially important in industries such as food and beverage, where the shelf life and safety of the product are paramount. The internal coating also helps in maintaining the original taste and quality of the contents, which is critical for customer satisfaction.

In addition to safety and preservation, internal lacquering machines contribute to the packaging’s mechanical properties. The lacquer provides an added layer of protection against corrosion and wear, extending the life of the packaging. This is particularly relevant for aluminum products that are often exposed to various environmental factors such as moisture, heat, and chemicals. The durability provided by the lacquer not only enhances the performance of the packaging but also reduces the likelihood of product loss due to leaks or contamination.

Another significant aspect of internal lacquering machines is their efficiency and precision. Modern machines are designed with advanced technology that allows for consistent and uniform application of the lacquer. This precision ensures that every package receives the same level of protection, which is essential for maintaining quality standards across production batches. Additionally, many lacquering machines are equipped with features that facilitate quick changeovers and adjustments, enabling manufacturers to adapt to different product types and sizes without downtime.

The choice of lacquer is also critical. Various formulations are available, each designed to meet specific requirements depending on the intended use of the packaging. For instance, some lacquers provide enhanced chemical resistance, while others may focus on food safety compliance. It is essential for manufacturers to select the appropriate lacquer that aligns with regulatory standards and customer expectations.

In summary, internal lacquering machines play a vital role in the aluminum and aluminum alloy packaging industry. They enhance product safety, improve durability, and ensure a high-quality finish, all of which are crucial for maintaining competitive advantage in the market. Understanding the functionalities and advantages of these machines can help manufacturers optimize their production processes and deliver superior packaging solutions to their customers.

One of the primary functions of an internal lacquering machine is to prevent contamination. The lacquer coating acts as a barrier between the metal and the contents within, thereby preventing any reactions that could compromise the quality of the product. This is especially important in industries such as food and beverage, where the shelf life and safety of the product are paramount. The internal coating also helps in maintaining the original taste and quality of the contents, which is critical for customer satisfaction.

In addition to safety and preservation, internal lacquering machines contribute to the packaging’s mechanical properties. The lacquer provides an added layer of protection against corrosion and wear, extending the life of the packaging. This is particularly relevant for aluminum products that are often exposed to various environmental factors such as moisture, heat, and chemicals. The durability provided by the lacquer not only enhances the performance of the packaging but also reduces the likelihood of product loss due to leaks or contamination.

Another significant aspect of internal lacquering machines is their efficiency and precision. Modern machines are designed with advanced technology that allows for consistent and uniform application of the lacquer. This precision ensures that every package receives the same level of protection, which is essential for maintaining quality standards across production batches. Additionally, many lacquering machines are equipped with features that facilitate quick changeovers and adjustments, enabling manufacturers to adapt to different product types and sizes without downtime.

The choice of lacquer is also critical. Various formulations are available, each designed to meet specific requirements depending on the intended use of the packaging. For instance, some lacquers provide enhanced chemical resistance, while others may focus on food safety compliance. It is essential for manufacturers to select the appropriate lacquer that aligns with regulatory standards and customer expectations.

In summary, internal lacquering machines play a vital role in the aluminum and aluminum alloy packaging industry. They enhance product safety, improve durability, and ensure a high-quality finish, all of which are crucial for maintaining competitive advantage in the market. Understanding the functionalities and advantages of these machines can help manufacturers optimize their production processes and deliver superior packaging solutions to their customers.

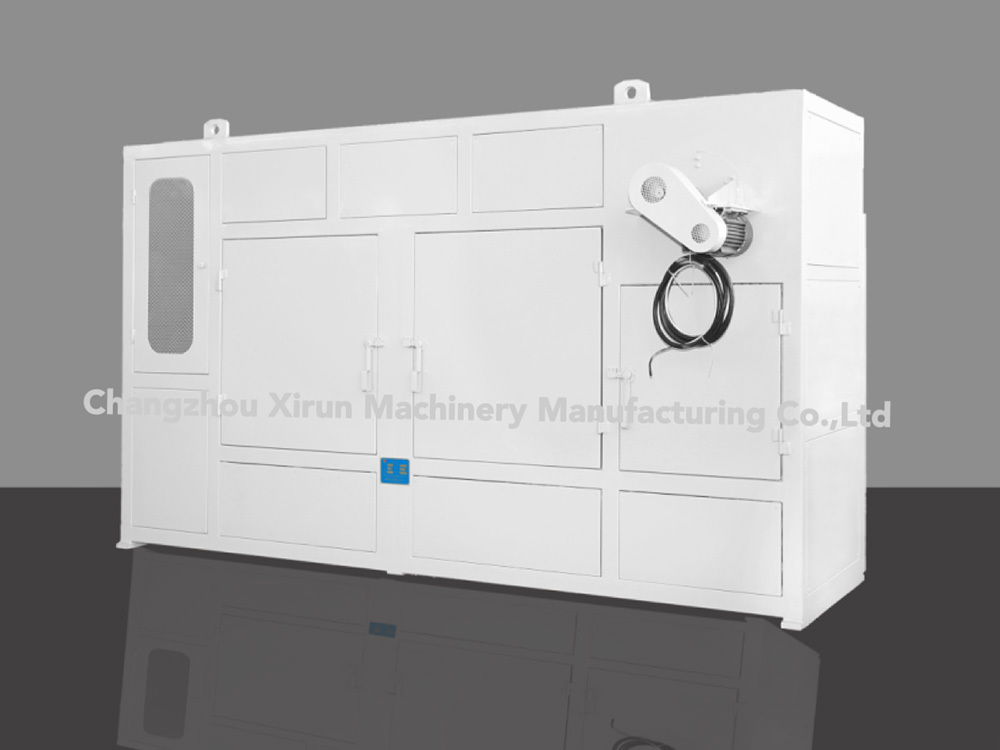

internal lacquering machine

Latest Blog