How to Optimize Your Cleaning Process for Aluminum Tubes: A Comprehensive Guide

How to Optimize Your Cleaning Process for Aluminum Tubes Cleaning aluminum tubes effectively is essential to maintain product quality and enhance overall operational efficiency. In this guide, we will explore various methods, techniques, and best practices to optimize your cleaning process. By implementing these strategies, you will ensure your aluminum tubes are spotless, free from contaminants,

Release time:

2026-01-22

How to Optimize Your Cleaning Process for Aluminum Tubes

Cleaning aluminum tubes effectively is essential to maintain product quality and enhance overall operational efficiency. In this guide, we will explore various methods, techniques, and best practices to optimize your cleaning process. By implementing these strategies, you will ensure your aluminum tubes are spotless, free from contaminants, and ready for subsequent processing.

Table of Contents

- Understanding Aluminum Tubes: Cleaning Needs and Challenges

- The Importance of Cleaning Aluminum Tubes in Manufacturing

- Effective Cleaning Methods for Aluminum Tubes

- Choosing the Right Chemical Solutions for Aluminum Tube Cleaning

- Mechanical Cleaning Techniques for Enhanced Efficiency

- Preventative Maintenance and Cleaning Schedules

- Safety Considerations When Cleaning Aluminum Tubes

- Frequently Asked Questions About Aluminum Tube Cleaning

- Conclusion

Understanding Aluminum Tubes: Cleaning Needs and Challenges

Aluminum tubes are widely used in various industries, including cosmetics, pharmaceuticals, and food and beverage packaging. Their lightweight and corrosion-resistant properties make them ideal for packaging applications. However, their cleaning needs can vary significantly based on the specific application and the type of contaminants present.

Contaminants such as oils, dust, and residues from manufacturing processes can adhere to aluminum surfaces, potentially compromising product quality. Therefore, understanding the unique challenges associated with cleaning aluminum tubes is the first step toward developing an optimized cleaning process.

The Importance of Cleaning Aluminum Tubes in Manufacturing

The cleaning process is critical in ensuring that aluminum tubes are free from contaminants that could affect the integrity and safety of the products they contain. **Here are several reasons why effective cleaning is vital:**

1. **Product Quality**: Clean tubes prevent contamination of the product, ensuring that it meets regulatory standards.

2. **Operational Efficiency**: A well-optimized cleaning process reduces downtime and enhances production flow.

3. **Cost-Effectiveness**: Regular and thorough cleaning can extend the lifespan of equipment and reduce maintenance costs.

4. **Compliance**: Many industries have stringent regulations regarding cleanliness. Adhering to these standards is crucial for compliance.

Effective Cleaning Methods for Aluminum Tubes

To achieve optimal cleanliness, various cleaning methods can be employed. We will examine some of the most effective techniques that can be tailored to your specific requirements.

1. Manual Cleaning Techniques

While automated systems are efficient, manual cleaning is sometimes necessary for intricate designs or small batches. **Here are some common manual cleaning techniques:**

- **Wiping with Solvent-Saturated Cloths**: Use non-abrasive cloths soaked in suitable solvents for quick cleaning.

- **Brushing**: Soft-bristle brushes can effectively remove stubborn debris without scratching the surface.

2. Ultrasonic Cleaning

Ultrasonic cleaning utilizes high-frequency sound waves to create microscopic bubbles that implode to dislodge contaminants. This method is particularly effective for complex shapes and surfaces, ensuring a thorough clean without physical contact.

3. High-Pressure Water Cleaning

High-pressure water cleaning can effectively remove loose contaminants and residues from the surface of aluminum tubes. When combined with appropriate detergents, this method can significantly enhance cleaning results.

Choosing the Right Chemical Solutions for Aluminum Tube Cleaning

Chemical agents play a crucial role in the cleaning process. Selecting the right cleaning solutions can influence the effectiveness and safety of the process. Consider the following factors when choosing chemical solutions:

1. Compatibility with Aluminum

Ensure that the cleaning agents are specifically formulated for use on aluminum surfaces. Harsh chemicals can lead to surface degradation and corrosion.

2. Type of Contaminants

Identify the type of contaminants present on the tubes. Oils, paints, and adhesives may require specific cleaning solutions designed to dissolve these materials effectively.

3. Environmental Considerations

Choosing eco-friendly cleaning agents not only aligns with sustainability goals but also reduces the risk of harmful exposure to workers.

Mechanical Cleaning Techniques for Enhanced Efficiency

Mechanical cleaning techniques can significantly improve the effectiveness and efficiency of the cleaning process. Some common practices include:

1. Abrasive Cleaning

Abrasive cleaning can remove heavy deposits and surface contaminants. However, it should be performed cautiously to avoid damaging the aluminum surface. Use non-metallic abrasives to minimize risks.

2. Automated Cleaning Systems

Investing in automated cleaning systems can save time and labor. These systems often combine multiple cleaning methods, ensuring a thorough clean with minimal manual intervention.

Preventative Maintenance and Cleaning Schedules

Establishing a regular cleaning schedule is essential for maintaining cleanliness and equipment efficiency. Consider the following factors when developing your cleaning schedule:

1. Frequency

Determine how often cleaning should occur based on production volume and the type of contaminants usually present.

2. Maintenance Checks

Regular maintenance checks of cleaning equipment can prevent breakdowns and ensure optimal performance.

3. Documentation

Keeping a detailed log of cleaning activities and maintenance checks can help identify patterns and areas for improvement.

Safety Considerations When Cleaning Aluminum Tubes

Safety should always be a priority in any cleaning operation. Here are some key safety considerations to keep in mind:

1. Personal Protective Equipment (PPE)

Ensure that all personnel involved in the cleaning process are equipped with appropriate PPE, including gloves, goggles, and respiratory protection if necessary.

2. Proper Ventilation

Work in well-ventilated areas, especially when using chemical agents, to minimize inhalation risks.

3. Training

Provide comprehensive training for staff on cleaning protocols and the proper handling of cleaning agents.

Frequently Asked Questions About Aluminum Tube Cleaning

1. What types of contaminants are commonly found on aluminum tubes?

Aluminum tubes can collect dust, oils, adhesives, and residues from manufacturing processes, which may require different cleaning methods.

2. How often should aluminum tubes be cleaned?

The cleaning frequency depends on production volume and the nature of contaminants but typically ranges from daily to weekly.

3. Are there specific chemicals I should avoid when cleaning aluminum?

Yes, avoid harsh acids or alkaline cleaners that can corrode aluminum surfaces. Always choose products specifically designed for aluminum.

4. Can ultrasonic cleaning be used for all types of aluminum tubes?

Ultrasonic cleaning is suitable for most aluminum tubes but may not be ideal for those with delicate coatings or finishes.

5. What are the benefits of automated cleaning systems?

Automated cleaning systems enhance efficiency, reduce labor costs, and ensure consistent cleaning results.

Conclusion

Optimizing the cleaning process for aluminum tubes is essential for maintaining product quality, operational efficiency, and compliance with industry standards. By understanding the cleaning needs of aluminum tubes and implementing effective cleaning methods, chemical solutions, and safety measures, we can ensure that our cleaning processes are both efficient and effective. Establishing a routine maintenance schedule and investing in suitable cleaning technology will further enhance the overall effectiveness of our operations. Through careful planning and execution, we can achieve the highest standards of cleanliness in aluminum tube manufacturing.

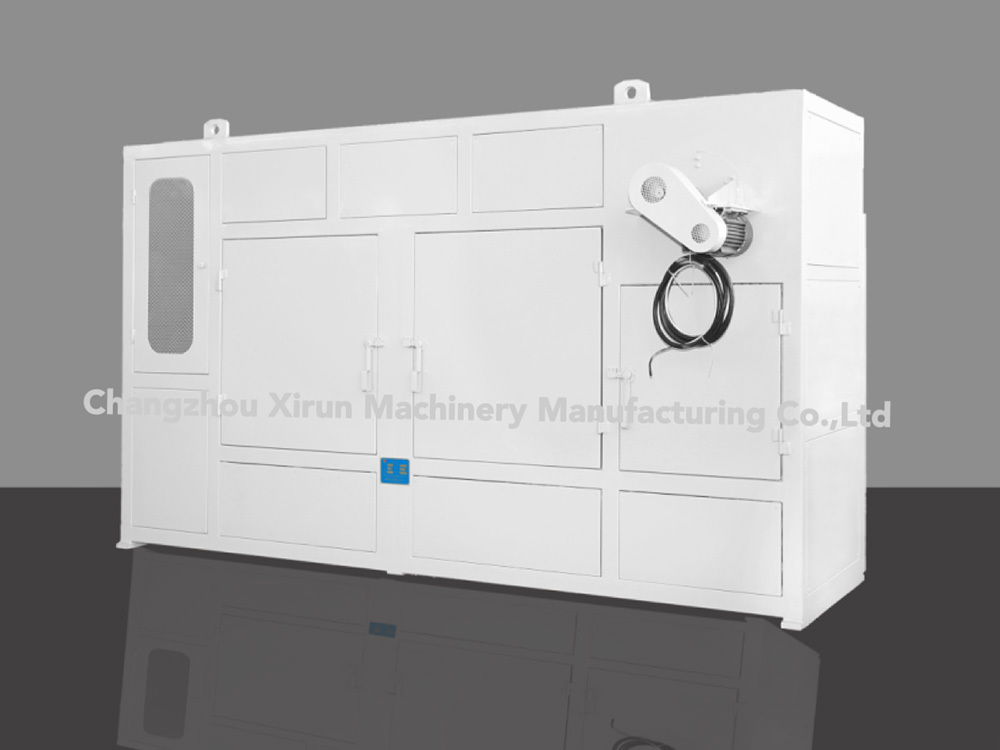

washing machine for aluminum tubes

Latest Blog